Elevating cannabis cultivation.

Vangarden is transforming the cannabis industry by marrying sustainable growing practices with revolutionary warehouse management.

When a warehouse wants to produce a certain amount of a product, they need to calculate the supplies and workers’ hours required, factor in any certifications those workers need, and organize task assignments and schedules. Grow houses additionally need to consider crop cycle timelines.

Vangarden believed that with today’s technology, there had to be a smarter solution, and they partnered with us to build it for them.

Revolutionizing warehouse management.

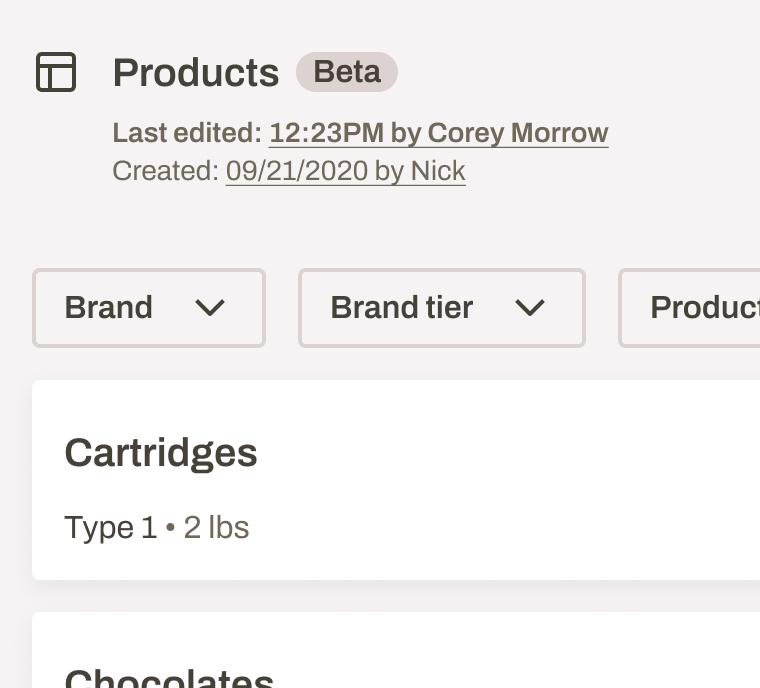

A manager can now input the product and quantity they want (for example, 100 lbs of gummies, 200 lbs of chocolates, 300 lbs of cartridges), and the app will organize all the details from what supplies are needed to what tasks need to be done when and by whom.

In other words, the software takes care of all the planning involved in running a production facility.

Automated task assignments.

Shift scheduling made easy–and employee-friendly.

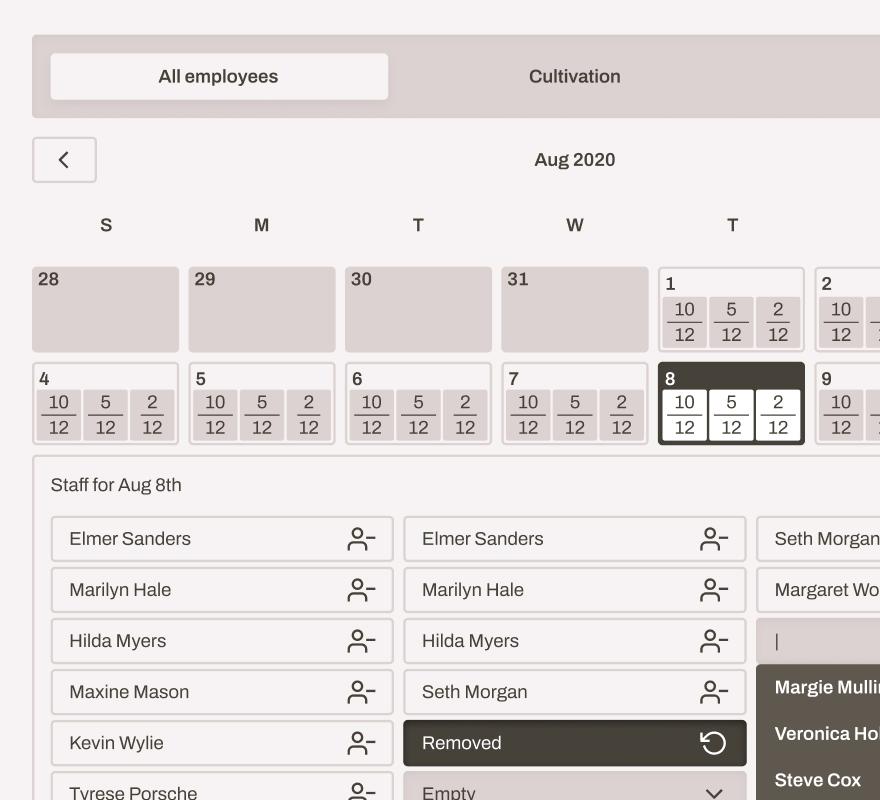

Instead of a shift manager attempting to wrangle the schedules of everyone in the facility, employees can now manage their own shifts: trading, offering, or picking up extra shifts from an automated pool.

Comprehensive admin controls.

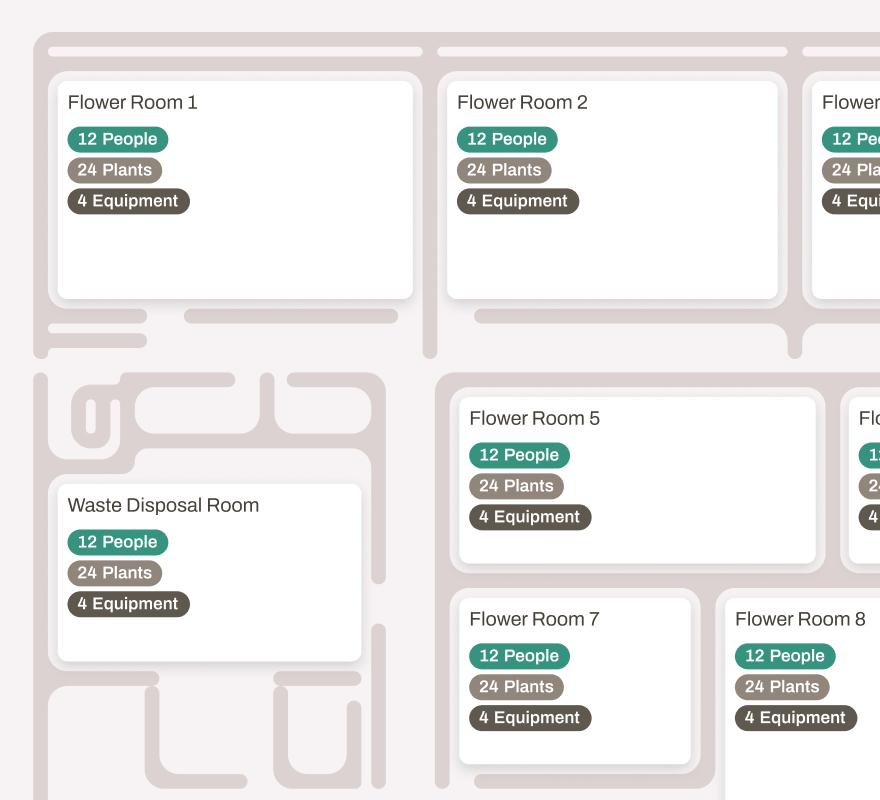

Enhanced security and efficiency with facility-wide tracking.

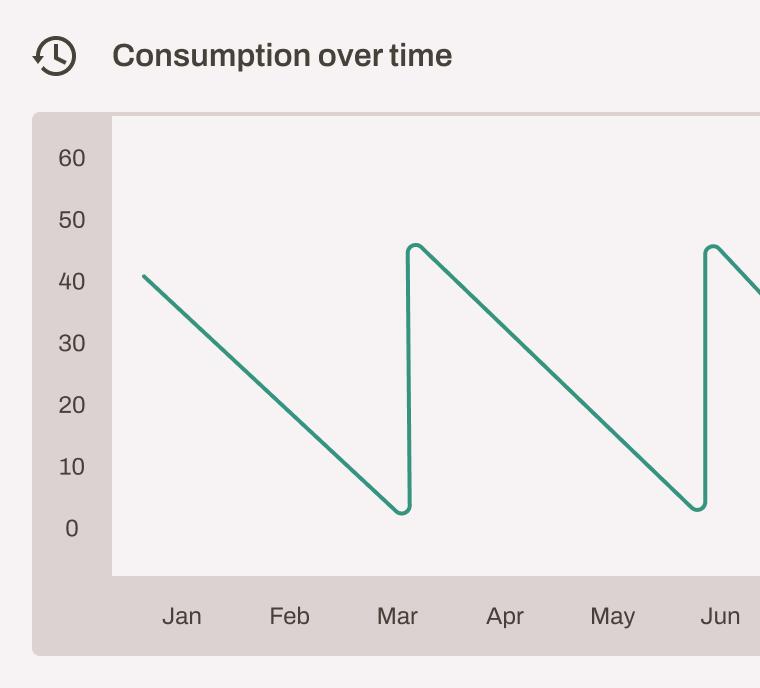

Precise inventory management.

Streamlined product management

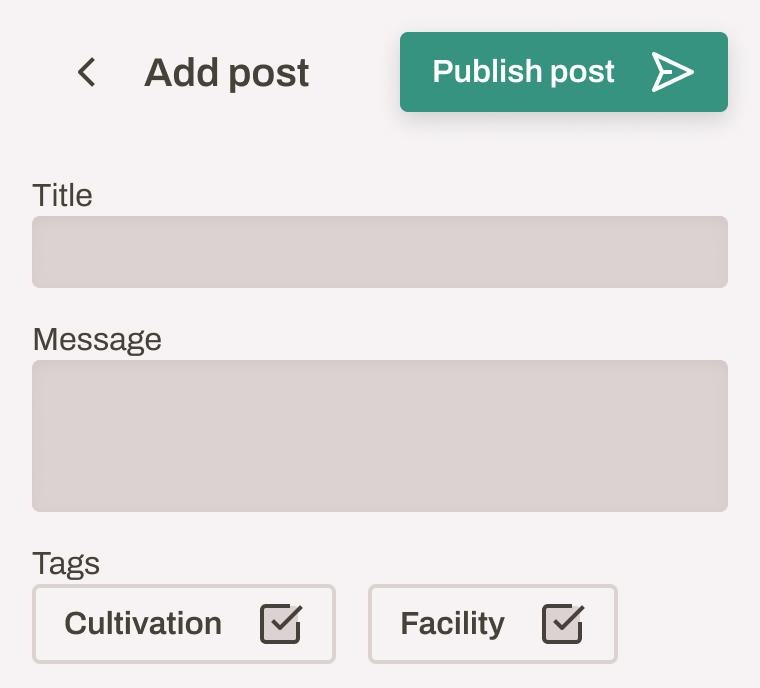

Improved company-wide communication.

Product Design: OnlyEdible.

Revolutionizing operations from seed to harvest.

Vangarden is ushering in a new era of smart cannabis cultivation. We’re excited to have given them a ground-breaking system that maximizes efficiency, reduces administrative overhead, and empowers their team.